Class II Standpipe System | NFPA 14

Class II Standpipe System according to NFPA 14

|

| Class II Standpipe System according to NFPA 14 |

First of all, let's define the standpipe system and clarify its different classes, then we will focus on class II.

Standpipe System

Definition:

An arrangement of piping, valves, hose connections, and associated equipment installed in a building or structure, with the hose connections located in such a manner that water can be discharged in streams or spray patterns through attached hose and nozzles.

Purpose:

Extinguishing a fire, thereby protecting the building & occupants.

Classes of Standpipe Systems.

Class I Systems.

A Class I standpipe system shall provide 21∕2 in. (65 mm) hose connections to supply water for use by fire departments and those trained in handling heavy fire streams.

Class II Systems.

A Class II standpipe system shall provide either 11∕2 in. (40 mm) hose stations to supply water for use by trained personnel or a hose connection for the fire department during

initial response.

A minimum 1 in. (25.4 mm) hose shall be permitted to be used for hose stations in light hazard occupancies where investigated and listed for this service and where approved by the AHJ.

Class III Systems.

A Class III standpipe system shall provide 11∕2 in. (40 mm) hose stations to supply water for use by trained personnel and 21∕2 in. (65 mm) hose connections to supply a larger volume of water for use by fire departments and those trained in handling heavy fire streams.

The remaining part of the article, we will talk about only class II.

Required type of class II standpipe system

- Class II standpipe systems shall be automatic wet systems

- Where piping is subject to freezing and where a fire brigade is trained to operate the system without fire department intervention, in which case an automatic dry or semiautomatic dry system shall be permitted.

- In a non-high-rise building, The Class II portion of a Class III system shall be automatic.

Location of class II standpipe System.

All portions of each floor level of the building are within 39.7 m of a hose connection provided with 11∕2 in. hose or within 36.6 m of a hose connection provided with less than 1in. hose.

Note that: Distances shall be measured along a path of travel originating at the hose connection.

Installation height of hose connection.

Hose connections and hose stations shall be unobstructed and shall be located not less than 0.9 m or more than 1.5 m above the floor.

Note that: This dimension shall be measured from the floor to the center of the hose valve as per the following figure.

|

| Hose Connection Installation Height |

Hose Stations Components & requirements:

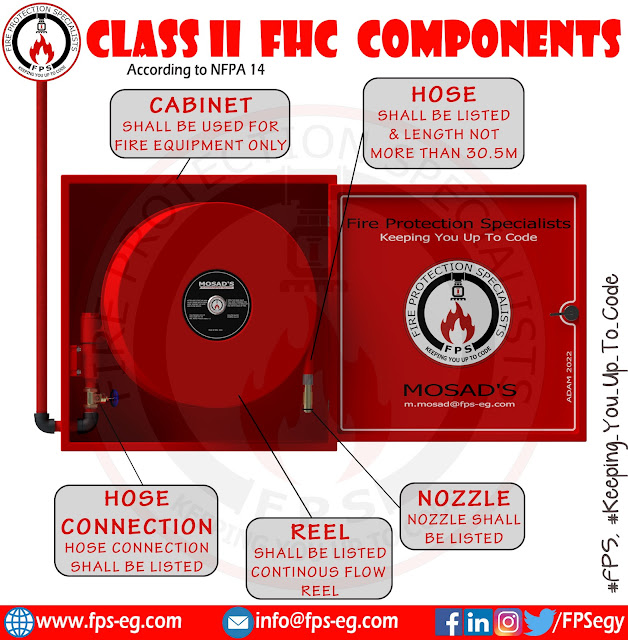

Class II hose station shall contain the following components according to the following figure:

|

| Class II Standpipe System Components |

1. Closets and Cabinets

- Closet or cabinet shall be used for only fire equipment & shall be marked to indicate the contents.

- Within the cabinet, the hose connections shall be located so that there are at least 50 mm between any part of the cabinet, other than the door and the handle of the valve when the valve is in any position ranging from fully open to fully closed.

2. Hose

- Hose length shall not be more than 30.5 m

- Hose shall be listed.

- Size of 11∕2 in. lined, collapsible or noncollapsible,

- Where using 1" hose, a listed noncollapsible hose shall be used.

3. Hose Rack & Reel

- Where using 11∕2 in. hose, it shall be equipped with a listed rack or approved storage method.

- Where using 1" hose, it shall be equipped with a listed continuous flow reel.

- Each rack or storage facility for hoses shall be provided with a label that includes the wording “FIRE HOSE FOR USE BY TRAINED PERSONNEL” and operating instructions.

4. Nozzle

- Nozzles shall be listed.

5. Hose Connections

- Hose valves shall be listed.

- Hose connections shall be located so that there is at least 76.2 mm clearance between any adjacent object and the handle of the valve when the valve is in any position ranging from fully open to fully closed.

Minimum Flow Rate.

The minimum flow rate for the hydraulically most remote Class II hose connection shall be 100 gpm.

Note that: Additional flow shall not be required where more than one hose connection is provided.

Minimum Design Pressure.

Hydraulically designed standpipe systems shall be designed to provide the waterflow rate of 100 gpm at a minimum residual pressure of 65 psi (4.5 bar) at the outlet of the hydraulically most remote class II hose connection.

Maximum Pressure at Hose Connections

- Where the residual pressure at the hose connection exceeds 100 psi, a listed pressure regulating device shall be provided to limit the residual pressure to 100 psi while flowing 100gpm.

- Where the static pressure at the hose connection exceeds 175 psi, a listed pressure regulating device shall be provided to limit static and residual pressures at the hose connection to no more than 175 psi.

Reference of the article:

NFPA 14 - 2019 edition (Standard for The Installation of Standpipe and Hose Systems)

Read Also:

Where Standpipe System is Required?!

Fire Department Connection According to NFPA 14

Floor Control Valve Assembly According to NFPA 13

Pipe Schedule Method According to NFPA 13

Sprinkler Characteristics According to NFPA 13

Sprinklers in Electrical Rooms According to NFPA 13

Return Bend Requirements According to NFPA 13

Pipe Schedules for Firefighting Sprinkler System According to NFPA 13

Md Akhlaq

ReplyDeletemdakhlaq114@gmail.com

ReplyDeletethnk you for sharing

ReplyDelete