Diesel Tank For Fire Fighting Pump | NFPA20

Diesel Tank For Fire Fighting Pump | NFPA20

|

| Diesel Tank For Fire Fighting Pump | NFPA20 |

General requirements:

The fuel supply tank and fuel shall be reserved exclusively for the fire pump diesel engine.

There shall be a separate fuel supply tank for each engine.

There shall be a separate fuel supply and return line for each engine.

Tanks shall be single wall or double wall, while using Single-wall fuel tanks, it shall be enclosed with a wall, curb, or dike sufficient to hold the entire capacity of the tank.

Tanks shall be securely mounted on noncombustible supports.

Fuel Supply Tank Capacity.

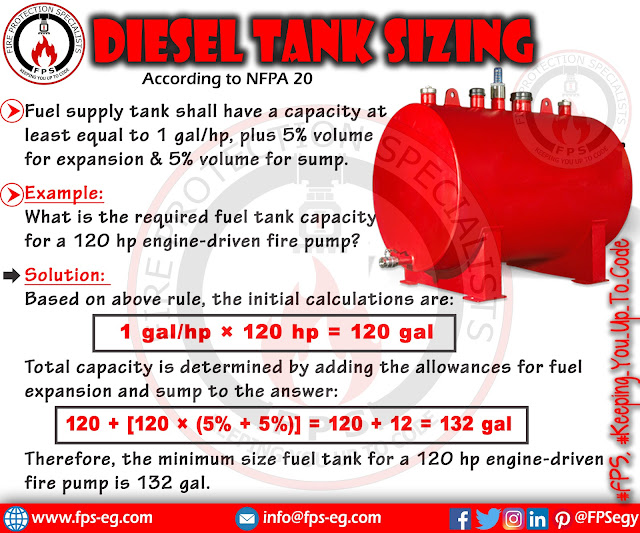

Fuel supply tank(s) shall have a capacity at least equal to 1 gallon per hp, plus 5 percent volume for expansion and 5 percent volume for sump.

Example on diesel tank sizing:

|

| Diesel Tank Sizing |

Fuel Supply Tank Location

Diesel fuel supply tanks shall be located above ground and shall not be buried.

Diesel fuel storage tanks preferably should be located inside the pump room or pump house, and the fill and vent lines should be extended outdoors.

Tank Connections.

Each tank shall have the following connections:

Fill connection.

Fill pipes shall enter the top of the tank and shall terminate within 6 in. of the bottom of the tank.

Drain connection.

Shall be located in the lowest point of the tank and size of 1 in. NPT.Vent connection.

- Normal vents shall be 2 in. NPT or sized according to ANSI/UL 142.- As an alternative, the normal vent can be at least as large as the largest filling or withdrawal connection, but in no case shall it be less than 11∕4 in. nominal inside diameter.

Engine supply connection.

The fuel supply pipe connection shall be located on a side of the tank so that 5 percent of the tank volume provides a sump volume not usable by the engine.Engine return connection.

The tank connection shall be no smaller than the fuel return piping from the engine.Fuel level switch connection.

The fuel tank shall have one 2 in. NPT threaded port in the top, near the center, of the tank to accommodate the low fuel level switch.Active fuel maintenance return connection.

References:

NFPA 20 - 2022 edition. (Standard for the Installation of Stationary Pumps for Fire Protection)

Stationary Fire Pumps and Standpipe Systems Handbook.

Fire Protection Handbook, 20th Edition.

Read Also:

Anti-Vortex Plate for Fire Protection

Fire Pump Suction Line Components

Jockey Pump Requirements & Sizing

Relief Valve for Centrifugal Fire Pump

451D40A12A

ReplyDeletekiralık hacker

hacker arıyorum

belek

kadriye

serik